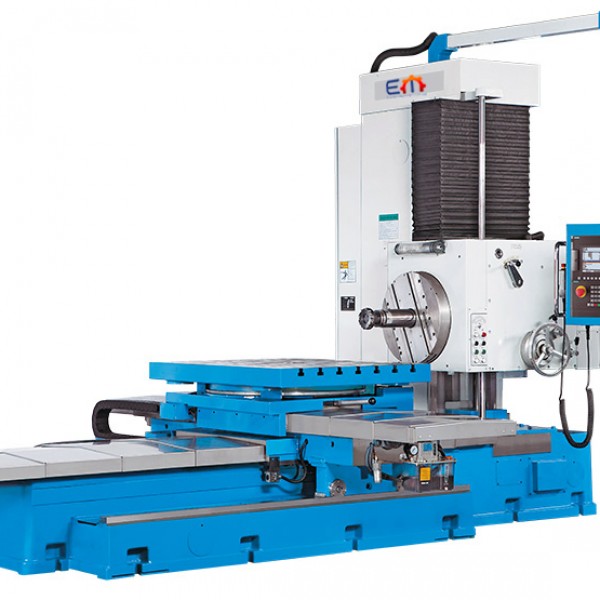

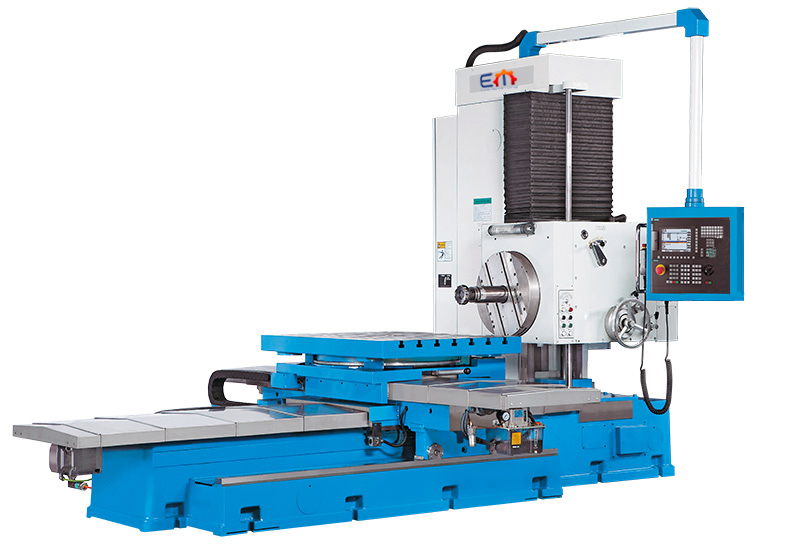

Feature:

Heavy-Duty CNC Drill Unit with Siemens 802D control for large and heavy parts

spindle speed and facing slide speed are infinitely variable

rotary table for a part weight up to 5 tons

3-axis CNC control

telescoping steel cover protects the guides from chips and dirt

rigid square guides are hardened and precision-ground to ensure exact work results for many years

wide machine bed with 4 guideways for linear table movement

precise table center support on cylindrical roller bearings

preloaded ball screws on all feed axes

automatic central lubrication system

axially adjustable drill spindle with speeds up to 1100 rpm

powerful main drive motor with 11 kW

Setup table with manual rotation

precise table center support provided by preloaded axial/radial cylindrical roller bearings

Control System:

Siemens Sinumerik 828 D

the top specialist for demanding milling operations

Highlights:

compact, robust, maintenance-free control panel-based CNC

comfortable program and parameter input via QWERTY keyboard

maximum machining precision

intelligent kinematic transformations for machining of cylindrical parts, and for angled workpiece levels

SINUMERIK MDynamics with the new Advanced Surface feature: for perfect part surfaces and shortest machining times in mold making applications

ShopMill: shortest programming time for single parts and small batch productions

programGUIDE: fastest machining time and maximum flexibility for large series productions

unique spectrum of technology cycles – from milling contours with residual material recognition to process measurements

Animated Elements: unique operation and programming assistance with animated sequences

modern data transfer options via USB stick, CF card and network (Ethernet)

Easy Message: maximum machine availability due to process monitoring per texting (SMS)

CNC hardware

control-panel based high-performance CNC Control

robust front control panel made of magnesium die-casting

integreated full-size QWERTY keyboard

10.4“ TFT color monitor

maintenance-free design (no buffer battery required)

CNC performance data and functions

SINUMERIK MDynamics package with Advanced Surface for mold making applications

tool changing time: ~2 ms (PPU 260/261) /~1 ms (PPU 280/281)

number of Look Ahead sets: 100 (PPU 260/261) / 150 (PPU 280/281)

Jerk-limited acceleration

dynamic feed-forward control

4-axis simultaneous interpolation (X, Y, Z and rotary axis)

linear, circular and helical interpolation

tapping without compensating chuck, plus thread cutting

oriented spindle holder

toggle between inch and metric units

FRAME concept for individual coordinate transformations, rotations, scaling and mirroring

100 adjustable zero offsets

synchronous actions and quick help function output

CNC technology cycles

technology cycles for programGUIDE and ShopMill work step programming are available

large selection of drilling cycles

large selection of milling cycles for standard geometries

large selection of position patterns for drilling and milling operations

High-speed settings for mold making applications

geometrie calculator for free contour input

machining cycle for contour pockets / contour spigots with isolated contours

Graphic features

Animated Elements: input help for machining parameters with animated sequences

graphical online help system, similar to PC system

graphical CNC simulation with level display

CNC tool management

display of tool and magazine data on one screen

tool management with plain-text tool names

loading/unloading feature for easy magazine assignment

number of tool edges: 256 (PPU 260/261) / 512 (PPU 280/281)

tool management with tool life monitoring

| BM 110 CNC – CNC BORING MACHINE | |

| working area | |

| travel X-axis | 1200 mm |

| travel Y-axis | 900 mm |

| travel Z-axis | 550 mm |

| travel W-axis | 1300 mm |

| facing slide travel | 160 mm |

| table dimensions | 1320×1010 mm |

| facing slide working diameter (max.) | 630 mm |

| table load capacity | 5000 kg |

| Spindle center-to-table distance | 5 – 905 mm |

| table rotation range | 360 ° |

| number of T-slots | 7 Pieces |

| T-slots, width | 22 mm |

| T-slots, spacing | 125 mm |

| cutting capacity | |

| drilling capacity | 50 mm |

| finish bore | 240 mm |

| headstock | |

| speed range | 12 – 1100 rpm |

| spindle diameter | 110 mm |

| headstock torque | 1100 Nm |

| spindle mount | BT 50 |

| facing slide speed | 4 – 125 rpm |

| facing slide torque (max.) | 1100 Nm |

| Vorschubkraft, axial (max.) | 13 kN |

| feed | |

| rapid feed X-axis | 5000 mm/min |

| rapid feed Y-axis | 5000 mm/min |

| rapid feed Z-axis | 5000 mm/min |

| rapid feed W-axis | 2060 mm/min |

| feed speed Z-axis | 0,5 – 1000 mm/min |

| facing slide feed | 1370 mm/min |

| accuracies | |

| positioning accuracy X-axis | 0,04 mm |

| positioning accuracy Y-axis | 0,05 mm |

| positioning accuracy Z-axis | 0,06 mm |

| repeatability X-axis | 0,015 mm |

| repeatability Y-axis | 0,015 mm |

| repeatability Z-axis | 0,015 mm |

| work table rotation accuracy | ± 6″ (4×90°) |

| work table repeatability | ± 3″ (4×90°) |

| drive capacity | |

| motor rating main drive | 11 kW |

| measures and weights | |

| overall dimensions | 5347x3020x2890 mm |

| weight | 12000 kg |

,

,

,